Protective interior packaging is the core strength of Arrow Crating and Packaging. With the recent innovations in foam materials and fabricating machinery AC&P will give you a custom case insert for absolute protection in transporting your valuable equipment. AC&P design engineers will choose a foam material that is suitable for your application and budget from the list below.

Protective interior packaging is the core strength of Arrow Crating and Packaging. With the recent innovations in foam materials and fabricating machinery AC&P will give you a custom case insert for absolute protection in transporting your valuable equipment. AC&P design engineers will choose a foam material that is suitable for your application and budget from the list below.

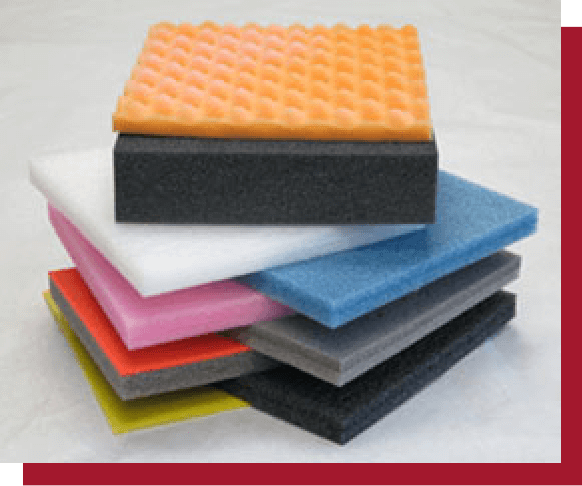

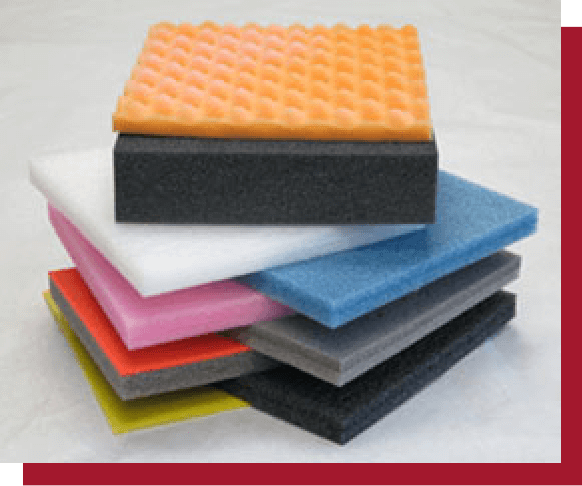

The most preferred and recently created especially for custom case foam inserts, our fine cell polyethylene foam is a 2.2# extruded material that fabricates extremely well with AC & P’s state of the art equipment. It is manufactured from 60% post-industrial resin thus giving your company the green initiative desired in today’s economy. It is charcoal in color with a smooth skin like appearance and meets CID-A-A-59136 (Formerly PPP-C-1752D).

Economical closed cell, non-absorbent, long lasting, highly resilient foam most commonly fabricated in black but other colors available. Pink anti-static polyethylene foam for extremely sensitive devices to prevent electrostatic discharge also available. Along with Prolam Plus tm Laminated PE Plank, this is a high performance product that can be fabricated in a precise manner that saves on heat welding or gluing when manufacturing end caps.

Low cost, open cell, very flexible foam, recommended as an inexpensive alternative for one way shipments and items that are less fragile. This foam is available in many colors and frequently used in higher volume applications where the product will not remain in its packaging. Available in antistat on both flat sheets and convoluted form.

More expensive yet most prevalent in protective foam used for display type packaging, open cell, highly- resilient, most often used in situations where the packaged product will remain in its packaging for extended amount of time, polyester foam will retain its color and keep from deteriorating over an extended length of time. Charcoal color most often used but other colors along with anti-static available.

Most expensive of the common packaging foams, moisture resistant, highly resilient, closed cell, extremely durable and most aesthetically pleasing of the foams, used in many medical applications.

Formulated with a special carbon black to provide conductive properties. Non-Sloughing, corrosion resistant our LDCN foam is ideal for long term storage of small electronic shipping parts. Foam die-cuts cleanly and can be incorporated into pin insertion pads, assembly tote tray inserts or wedge protection for trays.

Is a flocked simulated velvet foam. It is a unique, distinctive velour covering that creates a great impression for your products. Sim-U-Vel ™ is combined by a lamination to other foam materials with Polyester Polyurethane Foam being the most popular in the fabrication of Case Inserts and Presentation Boxes, although other foam base materials are also used depending upon the application. Sim-U-Vel ™ is manufactured in over (20) stock colors.

Method of punching out custom parts and shapes used for protective packaging and gaskets.

Process of creating an egg shape foam sheet used mostly as top and bottom cushions inside a carton to protect irregular shaped fragile items. This process is popular in the electronics industry using anti-stat polyurethane foam.

Computer controlled band saw used for three dimensional shapes.

precise capabilities in cutting, scoring, kiss cutting, perforating and variable depth routing up to 5” thick.

A method of adhering two parts (ex. foam to corrugated) using a cold glue spray adhesive created specifically for the packaging industry.

Another method of adhering two parts together without using a medium, only hot air to melt the foam enough to weld the parts together.

Most common way in combining two products together whether it be foam to foam or foam to another surface, this method using hot glue dispensed by either a gun or roller depending upon the application.

Arrow Crating and Packaging offers a complete packaging service using all of the above to complete a finished package that will protect and enhance your special product.